Products | ABB Motors

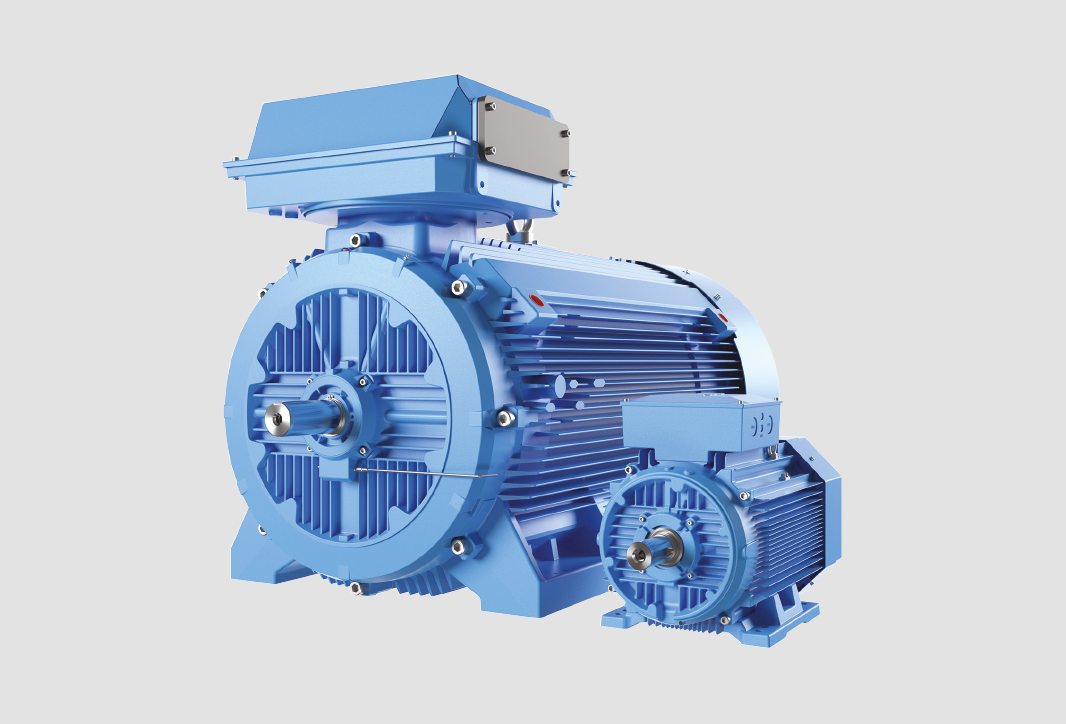

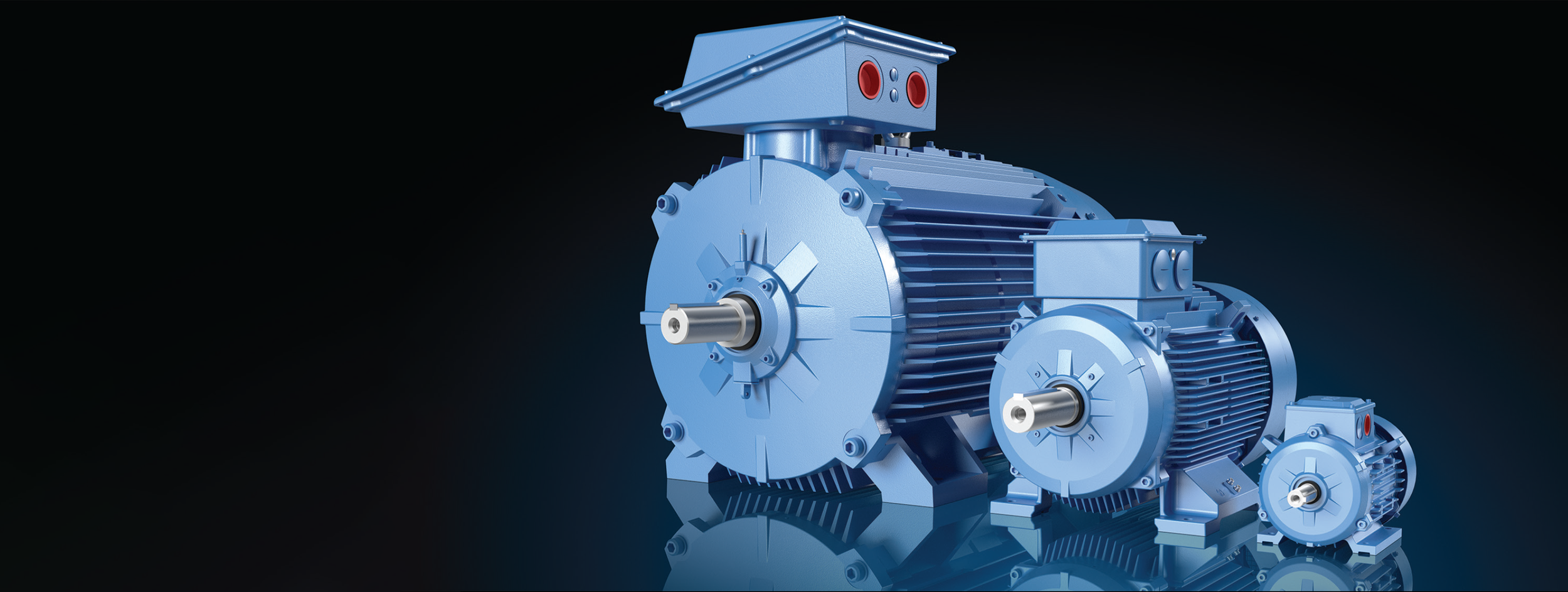

Cast Iron Process Performance Motors

ABB Cast Iron Process Performance motors are built for exceptional strength, durability, and reliability in the most demanding industrial environments. Engineered with a robust cast iron frame, these motors deliver outstanding performance in harsh conditions, ensuring long service life and consistent operation under heavy mechanical stress.

Ideal for process industries, manufacturing plants, and heavy-duty applications, ABB’s cast iron motors meet the highest standards of efficiency, availability, and dependability, making them the preferred choice for operations where uptime and performance are critical.

Cast Iron Process Performance Motors

ABB’s Cast Iron Process Performance motors are designed for maximum reliability and efficiency in the harshest of industrial conditions.

Covering IEC frame sizes 71 to 450 with power outputs from 0.25 to 1000 kW, these motors deliver high performance across a wide range of heavy-duty applications. Built with a robust cast iron housing, they are engineered to withstand mechanical stress, vibration, and demanding operating conditions while maintaining superior energy efficiency (IE2, IE3, and IE4 classes).

Ideal for pumps, fans, compressors, conveyors, mixers, and other process machinery, ABB’s cast iron motors combine mechanical strength with proven process reliability. Designed for versatility and global compatibility, they support both direct-on-line (DOL) and variable speed drive (VSD) operation, making them the perfect choice for process industries, chemical plants, paper mills, water treatment facilities, and power generation

Key Benefits

Exceptional mechanical strength, providing maximum rigidity and vibration resistance, ensuring reliable operation in the harshest of environments.

High energy efficiency, reducing energy consumption, operating costs, and environmental impact.

Long service life, with its precision-engineered components, high-grade insulation systems, and optimised cooling designs extend motor lifetime and reduce the risk of unplanned downtime.

Versatility in applications, suitable for both direct-on-line (DOL) and variable speed drive (VSD) operation, with flexible mounting options including foot, flange, and combination configurations.

Low maintenance requirements, robust bearings, high protection classes (up to IP66), and extended lubrication intervals minimise maintenance effort and cost.

Backed by ABB expertise - Supported by ABB’s global network of service centres, technical support, and spare parts availability for maximum peace of mind.

Typical usage & application

-

Aggregate Sites

Their durable construction withstands dust, vibration, and variable weather conditions common to quarry and aggregate sites.

-

Paper Mills

Their rugged design withstands high humidity, heat, and the constant load variations typical of mill environments.

-

Water Treatment facilities

Built for durability, ABB motors withstand moisture, corrosion, and fluctuating loads commonly found in treatment environments.

-

Power Generation

Their robust design ensures long service life and minimal maintenance, while high energy efficiency helps reduce operating costs and environmental impact.

Download the full catalogue

For complete technical specifications, performance data, and detailed product options, download the official ABB Cast Iron Process Performance Motors Catalogue.

his in-depth resource includes full details on power ratings, efficiency levels, frame sizes, dimensional drawings, mounting arrangements, and variant codes - everything you need to select the ideal motor for your application. Whether you’re specifying equipment for pumps, fans, compressors, or other heavy-duty industrial processes, the catalogue provides quick, accurate reference for engineers, maintenance teams, and procurement professionals alike, all in one convenient document.

Frequently Asked Questions

-

To be able to start premium efficiency motors (IE3-motors) we have increased the magnetic tripping level for some MMS to secure a start without tripping. The implementation became effective in August 2014.

The modern AF contactors from ABB have already from the beginning been designed to handle high efficiency motors.

When designing contactors to match the new efficient motors it is a balance between being able to close the contacts having a high inrush current peak and at the same time not causing an increased mechanical tear on the contact system.

ABB has been able to solve this using the AF technology, electronically controlled contactors. This technology allow us to fine tune the performance of the magnet system resulting in an optimised function for the job.

-

When you change a motor you always have to check how well the new motor data is matching the current design of the system. Mainly because there are many different motor brands and motor designs out in the market. For example, the motors from ABB have for many years had an efficiency in line with IE3 motors, so when comparing the motor data you may find IE3 motors having the same data as the old motor you are replacing.

If you are unsure, you can always use the ABB Selection tool for motor starters (SOC) to find the correct devices to be used when starting an IE3 motor.

We are constantly working with developing the coordination tables to match the market needs.

If fuses are used in the old installation, and if the starting current (locked rotor current) on the new motor are significantly higher than before, then you might need to check the fuse size. Use the same selecting rules as before.

If the starting current is high and too close to the fuse tripping curve, you may have some ageing of the fuse causing it to trip without having a “fault” in the system.

The sizing of the cable normally has margins and will be able to remain as is. We have not seen any cases when a change of the cable has been needed.

Thermal conditions will remain as they are from the even lower rated current.

-

The ABB selection tool for motor starters (SOC) indicates for which motors the selection is valid and this goes for all types of motors, IE1/IE2 as well as IE3.

When working with coordination, the motor data is the key data for the correct selection. And “IE2 data” can be valid also for IE3 motors, in the case when the locked rotor current is lower than 7,5 times the rated current. And this can absolutely be the case as the motor characteristics differ a lot both between brands, size and number of poles in use etc.

So for an optimised solution, always check the exact motor data. The same is valid for the wye-delta starters.

IE2 and IE1 motors installed don’t require changes and in these cases the IE1/IE2 coordination can be used for the repairing an old installation.

The same goes for equipment for export outside Europe, as there are large parts of the market that still are not demanding the use of premium efficiency motors.

Looking for a different type of motor?

Enquire about Our ABB Cast Iron Process Performance Motors

ContacT Us

Whether you’re interested in a specific service or would like to explore a customised solution, we are committed to delivering the highest level of quality and customer satisfaction.